Industry News

Nanocrystalline magnetic core: The "nanoscale revolution" from the laboratory to the trillion-dollar market

Amidst the wave of industrial transformation, marked by the breakthrough of new energy vehicle motor efficiency reaching 98%, a 40% reduction in energy consumption of 5G base stations, and an 88% increase in wireless charging efficiency, a nanocrystalline magnetic core, just 20 micrometers thick, is reshaping the global electromagnetic component industry chain in a disruptive manner. This "soft magnetic all-rounder", combining the advantages of silicon steel, permalloy, and ferrite, has become a core driving force in the technological trends of high-frequency, miniaturization, and greenification, thanks to its unique nanoscale crystal structure. Today, the editor from Shenzhen Jinxin Magnetic Materials will analyze multiple dimensions of nanocrystalline magnetic cores and systematically explain how they can leverage the trillion-dollar electronics industry upgrade.

1. Technological breakthrough of nanocrystalline magnetic cores: Leap from laboratory to industrialization 1. Ultra-high permeability: The static initial permeability can reach over 120,000, which is 10 times that of ferrite. It can respond quickly to high-frequency signals and reduce signal attenuation;

2. High saturation magnetic induction: The saturation magnetic flux density reaches 1.2-1.6T, which is 2.5 times that of ferrite, allowing it to withstand higher current density without saturation;

3. Low loss characteristics: Under the condition of 20kHz/0.5T, the loss is ≤30W/kg, which is 75% lower than that of ferrite, significantly reducing equipment heating;

4. Extreme environment adaptability: With a Curie temperature of 570℃, it can operate stably within the temperature range of -40℃ to 180℃, making it suitable for harsh industrial environments.

II. The Application Revolution of Nanocrystalline Magnetic Cores: Deep Penetration in Six Major Fields 1. New Energy Vehicles: Dual Breakthroughs in Efficiency and Cost

After adopting nanocrystalline cores in its drive motors, a certain enterprise achieved a 65% reduction in iron loss and a motor efficiency breakthrough of 98%. The power density of the on-board charger (OBC) was increased to 20 kW/kg, and the charging efficiency was improved to 95%. The battery management system (BMS) adopted nanocrystalline common mode inductors, resulting in a 45 dB improvement in EMI suppression and a 40% cost reduction;

2. Photovoltaic inverter: A dual leap in power density and efficiency

After adopting high-permeability nanocrystalline common-mode inductors for the 500kW centralized inverter, the number of EMC filter cores on the AC side is reduced by 30%, and the system efficiency surpasses 99.2%. The nanocrystalline-amorphous composite core achieves a working frequency of 300kHz, a power density of 60kW/L, and a 50% reduction in volume;

3. 5G communication: dual optimization of size and power consumption

After using nanocrystalline common mode inductors in the AAU module of a certain brand's 5G base station, the volume has been reduced by 45% and the power consumption has been reduced by 38%. The loss of TDK's PC95 series in the 28GHz millimeter-wave band is 70% lower than that of ferrite, supporting the antenna to achieve 64T64R configuration;

4. Wireless charging: Dual upgrade in efficiency and size

After adopting nanocrystalline magnetic sheets, a certain company has increased its charging efficiency to 88%, with an annual demand of 250 million pieces. The ultra-thin design has reduced the module volume to 1/4 of traditional inductors, and the anti-saturation capability has been improved by 3 times;

5. Medical equipment: dual improvement in precision and stability

The 12μm ultra-thin nanocrystalline magnetic core has a low coercivity of 0.25A/m. When applied to medical MRI superconducting magnets, it improves the magnetic field uniformity by 40% and accelerates the scanning speed by 30%;

6. Industrial control: dual optimization of frequency and loss

After the adoption of nanocrystalline cores in the field of inverter welding machines, the inductance frequency characteristics have been improved by 200%, and the copper loss has been reduced to 50% of that of ferrite. Gradient nanocrystallization technology has refined the grain size of the magnetic core surface to 4nm, resulting in a 35% reduction in high-frequency loss.

III. Industrial Landscape of Nanocrystalline Magnetic Cores: Global Competition and Domestic Substitution 1. International giants: Occupying 30% of the global market share, their series of nanocrystalline magnetic cores exhibit uniform thickness of 0.5μm, with a market share exceeding 55% in the iron cores of new energy vehicle motors; they have launched the world's first 12μm ultra-thin magnetic core, monopolizing the medical MRI market;

2. Chinese Strength: Mastering the preparation technology of ultra-thin strip material at the 18μm level, achieving import substitution in 5G base station inductors; establishing the world's first 10,000-ton continuous production line with a capacity of 15,000 tons per year; entering the supply chain, with annual shipments of wireless charging magnetic cores exceeding 60 million pieces;

3. Regional market: Europe and the United States focus on high-end manufacturing (such as customized nanocrystalline magnetic cores with loss requirements of ≤4W/kg), and undertake the transfer of global electronic manufacturing capacity (with the demand for mid-to-low-end magnetic cores increasing by 50% annually, and Chinese enterprises accounting for over 75% of the market share).

IV. Future Trends of Nanocrystalline Magnetic Cores: Three Major Directions in the Hundred Billion-Dollar Market 1. Technological Advancement: Breakthroughs in extreme technologies such as 8nm-level grain control and mass production of 8μm-level ultra-thin strips, achieving atomic-level magnetic domain control;

2. Scenario penetration: Develop specialized materials tailored for niche markets, such as new energy vehicle motors, 6G communication, nuclear fusion, and other high value-added markets;

3. Green manufacturing: Reduce carbon emissions throughout the entire life cycle through material innovation and process optimization.

In summary, amidst this global industrial restructuring, Chinese enterprises are transitioning from being "cost advantage providers" to "technology leaders". Nanocrystalline cores, a product of the "nanotechnology revolution" in soft magnetic materials, not only inject green momentum into industries such as new energy vehicles, 5G communications, and photovoltaic inverters, but also open up a new blue ocean of hundreds of billions of industries through technological breakthroughs and scenario penetration. In the future, with technological breakthroughs such as 8nm grain control and 6G dedicated materials, nanocrystalline cores will become the core engine driving the upgrading of the next-generation electronics industry.

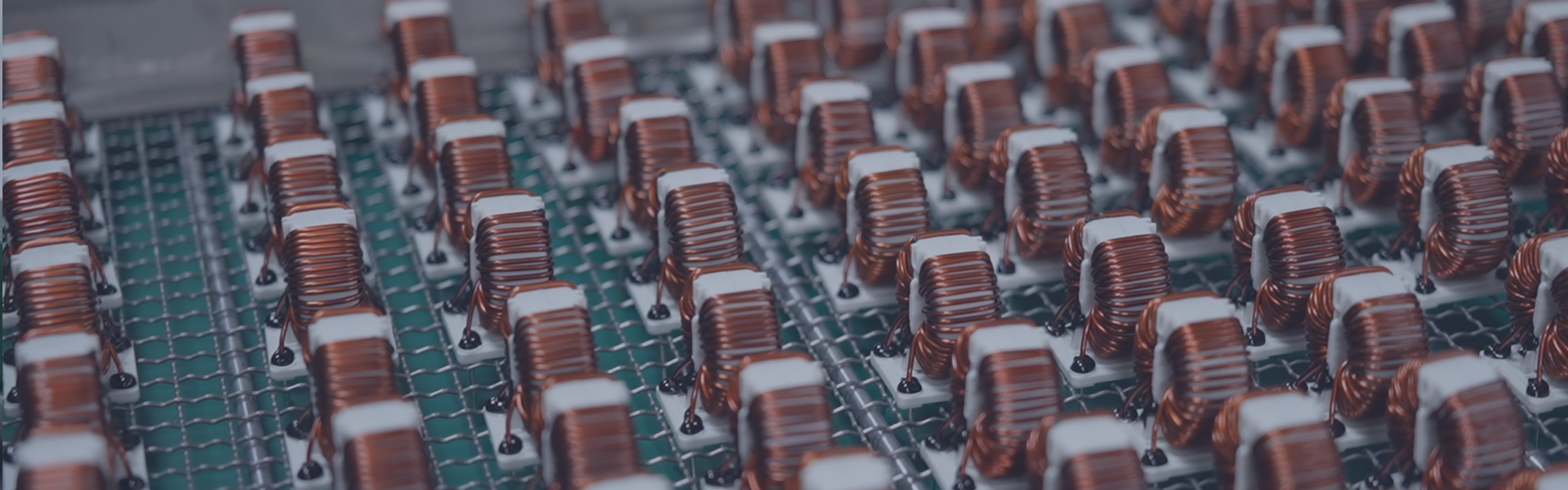

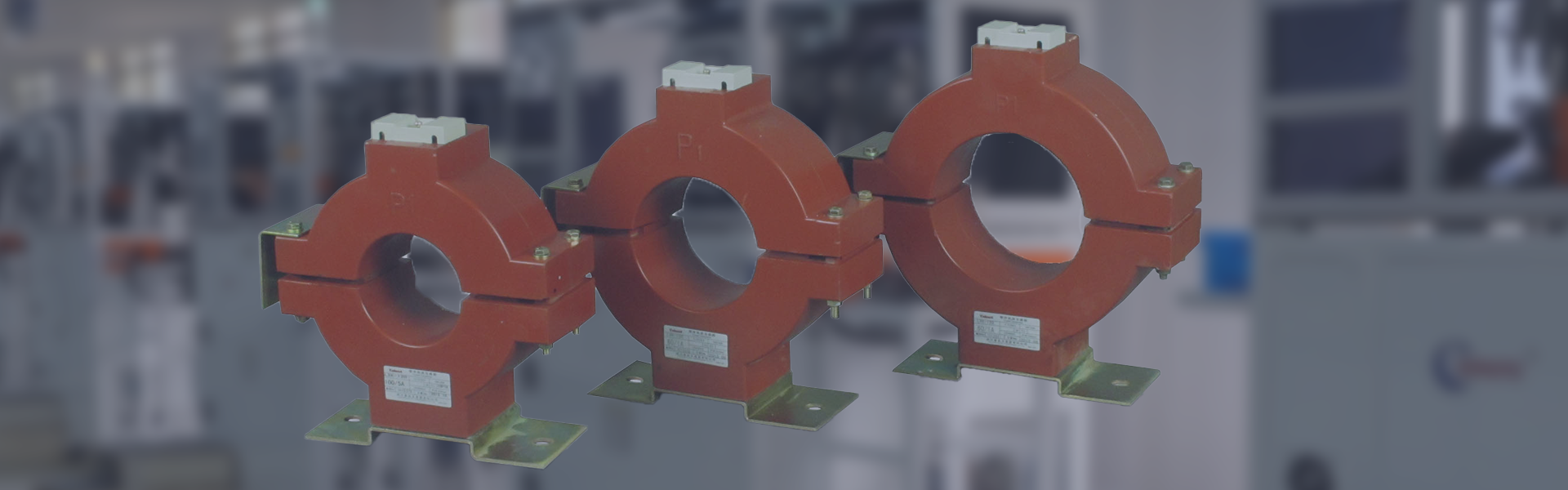

Hubei Manailun Technology Co., Ltd is dedicated to the research, development, production, and sales of amorphous, nanocrystalline, and permalloy magnetic core products. Our main products include nanocrystalline strip, ultra-microcrystalline iron core, ultra-microcrystalline magnetic core, permalloy magnetic core, high-power transformer iron core, nanocrystalline magnetic ring inductor, electromagnetic ring coil, open-close type transformer, common mode inductor coil, precision current transformer, and other products that exhibit excellent stability and high electrical parameters.

2025-12-01

2025-12-01